Our Products

VENEERS

Veneers are used to manufacture flat panels such as doors, cover plates and panels for cabinets, parquet, flooring and parts of Furniture

ADHESIVES

The adhesive is used to join wood materials together or dissimilar materials. Furniture production lines could be more productive with fast-curing adhesive.

OTHERS

We offer products such as MDFs, Wood Panels, Veneer Tape, Veneer Stitching Thread, Veneer Edge Lipping and PVC Edge Lipping.

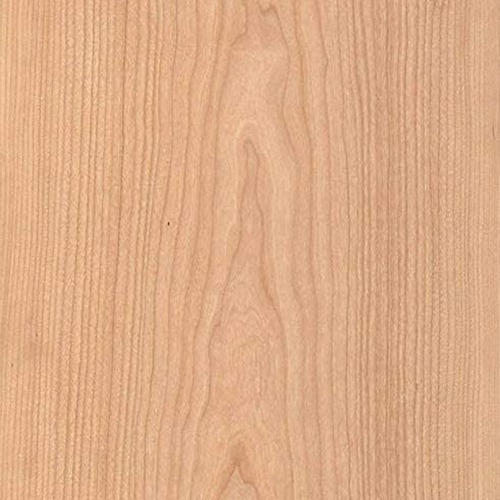

Veneers

Wood veneers are an excellent material choice for different furniture pieces as they look clean and come in variety of colours and styles.

Natural, solid wood is very vulnerable to moisture, that is it can result in warping. Veneers ensure you that your furnishing will not only look great but will also be long-lasting. We have a wide verity of veneer products directly imported from different parts of the world such as Germany, Italy, Spain etc. We deal with different segments within the construction industry such as interior decorators and contracting companies.

Natural Veneer

Natural veneers are made by slicing flitches each having a unique pattern. No two trees have identical pattern even if they are from the same species. Each piece of veneer has an authentic pattern which is derived from the species of tree it came from depending on the environment, soil and climate where it has grown.

The most common natural veneer wood species include Oak veneer, Ash veneer, Walnut veneer, Teak veneer, Maple veneer, Cherry veneer, Ebony veneer, Rosewood veneer, Sapele veneer, Anegre veneer, Eucalyptus veneer, Bamboo veneer, etc..

Real hardwood logs are thinly sliced to create veneer “leaves” which are then glued to an engineered panel we call a “plywood core”. The size of these thin slices generally is 1/50” thick and varied range in width. These thin Slices are called “leaves”. The leaves from the same log are adhered side by side, sequentially, to maintain colour and grain consistency. The panel is then finished in a clear or tinted finish that prevents water or moisture damage. It is easy to clean, and can be chemical resistant for laboratory environments

Reconstituted Veneer

Call it by any name, engineered veneer (EV) or reconstituted veneer (recon) or recomposed veneer (RV), it is a re-manufactured product. Reconstituted veneer is a special type of veneer that is created by using real wood from renewable sources to create a look alike of rare or exotic wood species. These veneers are made by slicing artificial logs made from light-coloured softer hardwoods, such as Basswood, Obeche, or Poplar. These logs are manoeuvred by slicing techniques, gluing schemes and colour staining so as to create a new man-made log.

It is an excellent eco-friendly alternative for most customers. The reconstituted veneer is engineered using various templates and pre-developed dye casts and they are glued together in blocks.

Engineered hardwood panels consists of an inner layer of plywood or high-density fibre beneath a top layer of hardwood veneer. This veneer layer gives your engineered furnishing the appearance of solid hardwood while minimizing the amount of raw lumber wasted in the process. The different ways of cutting the wood leads to different types of engineered wood veneers. Creation techniques of the veneer layer will influence its appearance and quality.

These techniques can be replicated repeatedly to make sure all panels look almost identical. It is environmentally friendly as they use common trees with very little wastage.

Balancer Popular Sheets

Wonder what is a balance veneer and why is it required? Backer or Balance grade veneers as they may be referred are commonly used on the reverse side of a panel. It ensures the panel stays flat. When the panel is veneered only on one side and its surface area is large, the panel undergoes stress and will cause the panel to warp.

Ambient humidity fluctuation due to season changes cause wood to expand and contract which can in turn lead the entire veneer part of the panel to grow and shrink. The movement occurs even when the panel has any type of finish applied on it.

So, it is advisable to use a balance veneer as it evens the stress caused by the expansion and contraction of wood cells in the veneer. When we bind a veneer on both sides of the panel, both sides equally expand and contract which leads the panel to be “balanced” as the stress of the wood cell movement will be same on both sides of the wood panel helping it stay flat

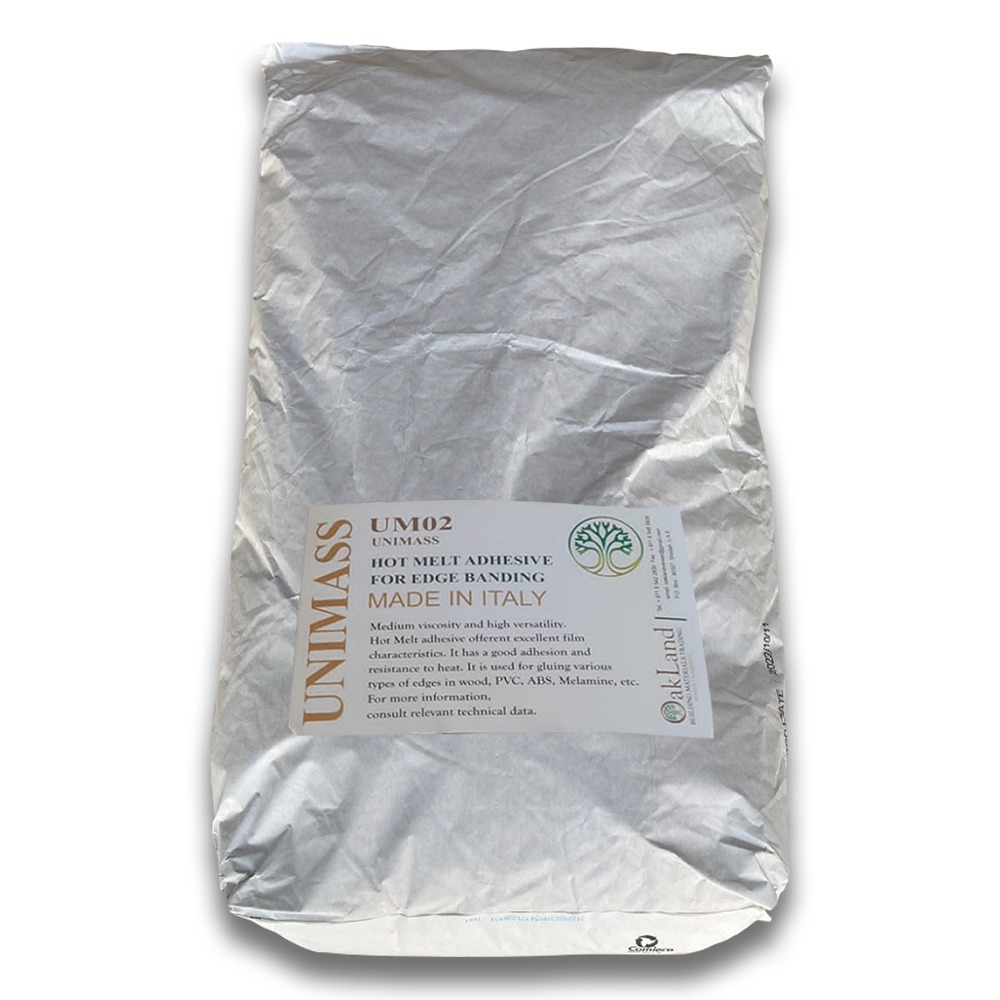

Adhesives

Powder Glue For Hot Press

Hot Melt Adhesive

White Glue

Water Resistant Glue

Universal Contact Adhesive

Others